Lead’s last hurrah?

Richard Atkins evaluates the latest (and last?) high-performance game cartridge loaded with lead shot

The latest news about the ongoing move away from lead shot now indicates that the banning of lead shot in game cartridges

will commence within five years of an implementation process beginning in 2024. With a delay in prospect, some cartridge makers are still introducing new lead shot game loads. The latest Gamebore cartridge featured here, the Black Gold Game UER (Ultimate Extended Range), uses their new Bio-Wad. This eco-friendly wad will disintegrate into the ground – soil or grassland – within a claimed 30 days.

Time will be dependant upon the weather, of course, but being water soluble it will degrade faster than compostable wads.

I was intrigued to receive samples of these new cartridges for review, because I had imagined that all new game cartridges would contain one of the emerging non-lead varieties of shot material. I was therefore interested to see what this brand-new lead shot game load with the eco-friendly Bio- Wad has to offer. It may also provide a useful yardstick for comparison with new non-lead cartridges.

Components

A key component in the cartridge is the brown, water-soluble eco-friendly Bio-Wad. Key among its features is the protective shot cup. It has four longitudinal slits that form the shot cup petals and are formed as part of the injection moulding process.

One feature claimed for these slits is that their edges have a 45° angle (most wads have straight/plain edge). They are designed to ensure that the edges of each petal overlap the adjacent edge to reduce the chance of shot pellets pushing though the gaps and thus contacting the sides of the bore. This is not, in fact, critical when used – as here – with lead shot, but it is with harder steel shot.

Due to the 70mm case and lead shot load taking up less space than steel shot, there is room for a cushioning centre section between the shot cup and the Quad Seal gas seal at the wad’s base. Steel shot biopolymer wads frequently omit or have only a very small collapsible centre section due to the additional space that is taken up by less dense steel shot.

One notable difference with using biopolymers to replace oil-based HDPE material to make eco-friendly biodegradable wads is their increased thickness, necessitated by their reduced strength.

This is clear in the shot cup petals. The Bio- Wad in this cartridge has the same petal thickness as that of those in Gamebore’s steel shot options, at 0.043″ (1.1mm) thick. I cut the conventional HDPE plastic wad from a Victory Starlight 32g lead shot game cartridge and the wad petals measured just 0.021″ (0.53mm) thick.

Biopolymers are also denser than HDPE plastic. The combination of greater thickness and denser material results in the Bio-Wad weighing 97gr, while the Victory plastic wad weighs 32gr.

Gamebore claim that the extra weight is an advantage in that it enables the cup “to travel even further with the shot still enclosed” for extended range performance of these cartridges for high-bird shooting. To what extent this is true I cannot measure or comment; all that really matters is to

discover how good the patterns are at range.

The shot

The lead shot is Gamebore’s Diamond Shot Xtra. It has a high antimony content, making it extremely hard as can be seen in the shot crush value. It is in fact the hardest (smallest crush value percentage) of any shot I have evaluated. This is, in part, due to the large pellet size but is mostly a results of the high antimony content.

Gamebore make their own lead shot, which is graded for size, polished and then tumbled in the special coating that gives Diamond Shot its characteristic shiny appearance. It is used in place of the more usual graphite.

The shot size marked on the carton is No. 4, with the metric shot diameter of 3.25mm marked below. I did a full pellet count, which produced 152 pellets per load and 137 per ounce. This is nominally the size and pellet count for UK No. 3 lead shot, which indicates that the No. 4 marking refers to the US

shot size. This is something to take note of when ordering your cartridges. I was a little surprised about the large shot size, because No. 3 lead has quite a low pellet count but will retain massive energy at distance.

It is long established that in most circumstances it is pattern density that fails before pellet energy. These pellets will have energy to spare, so the patterns become extra important.

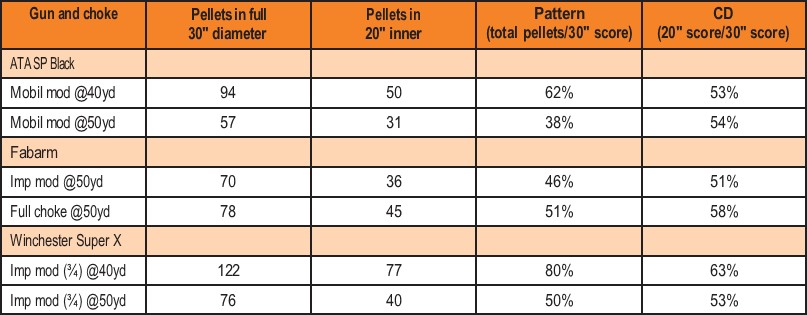

I submitted samples of these cartridges to the Birmingham Proof Laboratory for testing, with the results in the chart overleaf.

Analysis

The proof results show that the pressure and velocity are modest, the pressure with the RS double base powder exclusively used by Gamebore in the UK being over 200 bar inside the maximum. The low SD figure shows that consistency excellent.

The 357m/s at 2.5m is also a little lower than typical game cartridges but the shot size will ensure that energy at range is more than adequate. Larger shot retains its energy better than smaller shot.

Patterns

Pattern performance is important because it is pellets that kill targets, not percentages. But we need to know what percentage patterns we are getting and how many pellets there are in the pattern, otherwise you cannot be fully aware of how your gun is performing. Too few pellets in the pattern at the range you intend to use as your maximum will mean too many gaps in the pattern to ensure regular humane kills.

My first set of patterns were using my Mobil choke gun with the mod (½) extended choke fitted. I shot patterns at 40yd and 50yd because 40yd is typically a good-range shot for a lot of game shooting. I also patterned at 50yd because these cartridges are marketed as Ultimate Extended Range.

I am also aware that the additional 10yd can have a profound effect on patterns – more so than many shooters seem to realise. I often hear that such and such a cartridge “kills well at 40-50yd” as though there is not much difference. I can assure you there is; a lot goes on in those extra 10yd. The pattern results here illustrate this point. In fact they proved more revealing than expected.

I chose the mod (½) Mobil choke first because it is a widely used choke. It is used in numerous guns by makers who sell very well-priced guns and is proving popular with those who want a steel-proofed gun without breaking the bank. However, although the 40yd result gave 2% over the half-choke percentage, at 62%, the 50yd result was disappointing at 3% less than the nominal for this choke.

Continuing with the principle of buying guns to suit steel shot, I tried the steel proofed Fabarm O/U I bought for similar reasons. It has a unique choke system called Exis chokes, which have a hyperbolic internal profile that permits up to full choke with steel shot. The UER cartridges are lead, but I wondered how they would work with these chokes, which I patterned at 50yd.

As my chart shows, the Exis chokes performed well but pellet count in the 30″ circle at 50yd did not show the uplift I hoped for with more choke (Imp mod and full).

I decided to see if my faithful old Winchester Super X semi-auto with 30″ Imp mod fixed choke and 2¾” chamber would handle these cartridges better. From 40 years plus of using it for many hundreds of cartridge tests I know that this barrel responds well to this type of cartridge. Note that both steel proofed O/U guns used have 3″ (76mm) chambers. How relevant this may be is hard to evaluate.

This barrel has produced pattern percentages of slightly under ¼ choke (with soft shot in fast, budget clay loads) up to more than full choke percentages with premium, hard shot in moderate velocity clay loads and high-performance game loads.

That different cartridges can produce such a wide range of pattern percentages from the same fixed choke barrel is something that not all shooters may be aware of.

As the results in the main chart show, the fixed choke barrel and chamber length matching the cartridge worked out very well indeed. Given the hard shot, modest velocity and large pellet size, this is the kind of result I was hoping for. At 40yd the pattern is devastating and at 50yd still virtually matched the Exis full choke result.

These results are what I obtained with my guns, but do reinforce why I urge shooters to test their own guns with the cartridges they intend to use. This is especially true now, when we are all facing change. The results also make it abundantly clear that you cannot assume that because you have a particular choke in your gun then it will produce the results the charts may indicate with every cartridge.

Observations

It is clear that some guns, bores and choke profiles, plus chamber length combinations, do affect results. The move towards steel shot it makes it even clearer that we are losing some options and flexibility compared with the lead shot loads we are used to. The CIP suggested limits, particularly the maximum half choke with high-performance steel cartridges, is an obvious limitation.

More work is planned to investigate this topic in greater depth but for now the only way to know how your equipment performs is to test it.

The annular ribs around the outside of the Bio-Wad shot cup are there to reduce barrel contact and friction according to the literature. However, the ability of a soft

and flexible material to resist the enormous outward forces that the rapidly accelerating shot load produces would appear limited. The heavy plastic fouling I experienced in my barrels indicates considerable contact.

I obtained advice on how to remove this biopolymer fouling (as it proved stubborn to remove) from a very experienced shooter who was also trying the UER cartridges.

He suggested pouring hot water down the barrels. The hot water softened the plastic quite quickly and made it easier to scrub the residue out. This worked fine at home, but I also needed to clean the bores while out pattern testing, because I like to start each test with a clean bore. I resorted to using bore cleaner and my Magic Bore hand cleaning rod.

Conclusions

As their name suggests the UER cartridges evaluated here are intended for extreme range. The shot size, being so large, has energy to spare as the totally flattened pellets falling from the pattern plate at 50yd clearly confirm. However, large shot sizes mean fewer pellets in the pattern and even at 50yd with the best performing Imp mod fixed choke, pattern density is becoming marginal. Those who feel they are up to taking high birds further out than this will need to be very sure of how their gun performs.

My preference, and advice, is that the No. 5 shot (UK No. 4) option would be a better choice for filling the pattern – and the bag. There is also a 36g shot load offered. I believe there are very few among us who can consistently connect with the highest birds at a range beyond the killing energy of UK No. 4 shot.

This high-performance cartridge retails for around £585/1000. This compares with £500/1000 for Gamebore Dark Storm 32g fibre wad with Quad Seal obturator disc. The Bio-Wad must account for much of the additional cost.