Legislation

Shooting

Trigger happy

Longthorne Gunmakers explain the science and mechanics behind shotgun triggers credit: Archant Most shooters aspire to having a crisp and light trigger pull in their shotgun, one which is repeatable for top and bottom barrel or left and right (in the case of side-by-sides). The reason being, the gun should react as soon as you

Would you like to appear on our site? We offer sponsored articles and advertising to put you in front of our readers. Find out more

Longthorne Gunmakers explain the science and mechanics behind shotgun triggers

Most shooters aspire to having a crisp and light trigger pull in their shotgun, one which is repeatable for top and bottom barrel or left and right (in the case of side-by-sides). The reason being, the gun should react as soon as you think ‘pull’. In a heavy trigger, the user can inadvertently pull the gun off to one side or slow the swing, which can also be generally distracting.

Shotgun triggers are designed to be pulled with a swift, predictable action allowing the shooter to judge the lead on a moving target confidently knowing that the gun will fire as and when needed. This is as opposed to the trigger in a rifle where the target is usually stationary so the exact time when the trigger releases is not as critical.

In a shotgun it is preferable to have between ½mm and 1mm of travel on the trigger, incorporating a softer spring (approximately 1lb pressure) so that the shooter can feel the trigger even with gloves on and not discharge the weapon instantaneously. In true sidelocks, this is a lot easier to achieve than in a side-plated boxlock because of the fully independent lock work in an action of this type.

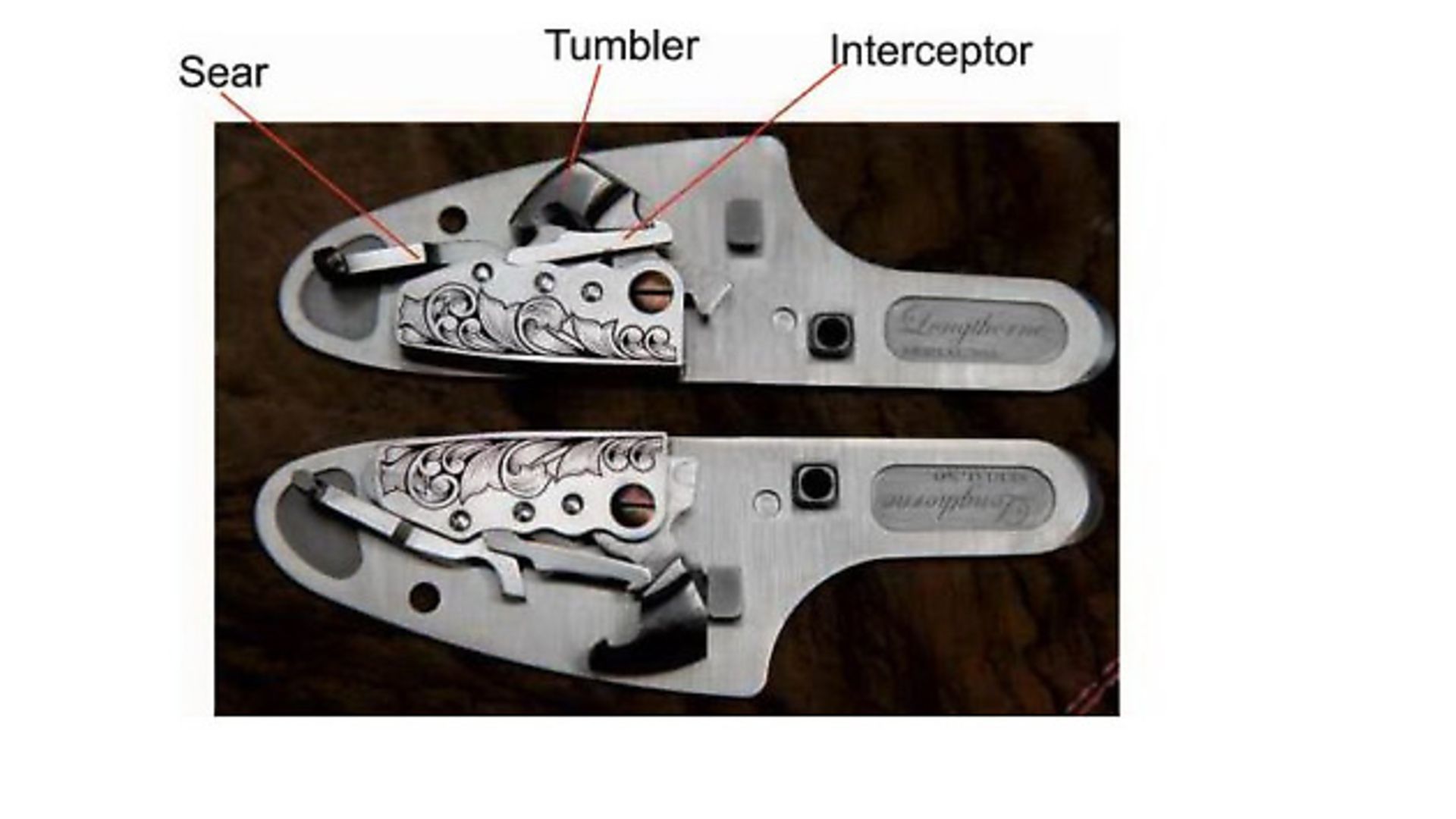

In a true sidelock the trigger-pull weight is altered by a combination of changing the sear angle and spring tensions to achieve the optimum trigger pull of around 3lb. Here at Longthorne, we use a trigger pull gauge to measure this; it is possible to make the trigger-pull weight marginally heavier if required and, although rare, occasionally clients do request this.

The ‘lock time’ is also critical in achieving the perfect trigger pull – this is the time the gun takes to strike to the firing pin and also to switch from the first to the second barrel. In our true sidelocks this is achieved using an inertia mechanism to switch from one barrel to the other and the length of the sear leg engagement on the inertia block is kept to a minimum to shorten the switchover time.

Every component in the mechanism plays a critical role and for this reason the more accurately manufactured the parts are, the easier this is to achieve and maintain consistently. The position of the trigger should ideally be far back in the trigger guard for a few reasons: it avoids your third finger impacting on the trigger guard, it is more aesthetically pleasing, and easier to reach.

The trigger should be designed so that it positions your finger close to the tip of the trigger blade, but the design should not encourage your finger to slip off the tip of it or become trapped underneath or behind.

In some of our models we insert a hollow oval shape at the top of our triggers; this is not only aesthetic, it also contributes towards the lightness of the trigger and positions the finger at the tip of the trigger, not allowing it to ride upwards, keeping the trigger pull weight consistent. If you have a long ‘lever’, the trigger-pull weight is reduced but the amount of travel is increased; if the trigger is pulled from closer to the action body, the weight is increased and the travel reduced.

Not all shooters are the same, and at Longthorne we work with our clients to ensure that the gun they have commissioned suits them. For example, we recently added trigger extensions to the tips of the triggers in a pair of guns to meet the requirement of our client with quite small fingers. We believe that these little touches are important and make our guns more personal to their owners, contributing towards their overall shooting experience.

Related articles

Legislation

Guns at auction

Longthorne Gunmakers explain the science and mechanics behind shotgun triggers credit: Archant Most shooters aspire to having a crisp and light trigger pull in their shotgun, one which is repeatable f...

By Time Well Spent

Game

Shooting

Shotguns

Drenched and disappointed

Longthorne Gunmakers explain the science and mechanics behind shotgun triggers credit: Archant Most shooters aspire to having a crisp and light trigger pull in their shotgun, one which is repeatable f...

By Time Well Spent

Get the latest news delivered direct to your door

Subscribe to Sporting Gun

Subscribe to Sporting Gun magazine and immerse yourself in the world of clay, game and rough shooting. As the leading monthly publication for passionate shooters at all levels, Sporting Gun delivers expert advice, practical tips and in-depth reviews to enhance your skills and enjoyment of the sport.

With features ranging from gundog training to pigeon shooting, and wildfowling to equipment recommendations, you’ll gain valuable insights from professional shooters and industry experts. A subscription not only saves you money on the cover price but also includes £2 million Public Liability Insurance, covering the use of shotguns, rifles and airguns for both recreational and professional use.

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.