★ Win a Schöffel Country shooting coat for everyone in your syndicate worth up to £6,000! Enter here ★

The difference between demibloc and monobloc barrels

Learn the difference between demibloc barrels and monobloc barrels, their respective strengths and weaknesses, and why most over-and-unders are made with monobloc

Barrel construction is the most poorly understood areas of gun manufacture, but also one of the most commented on.

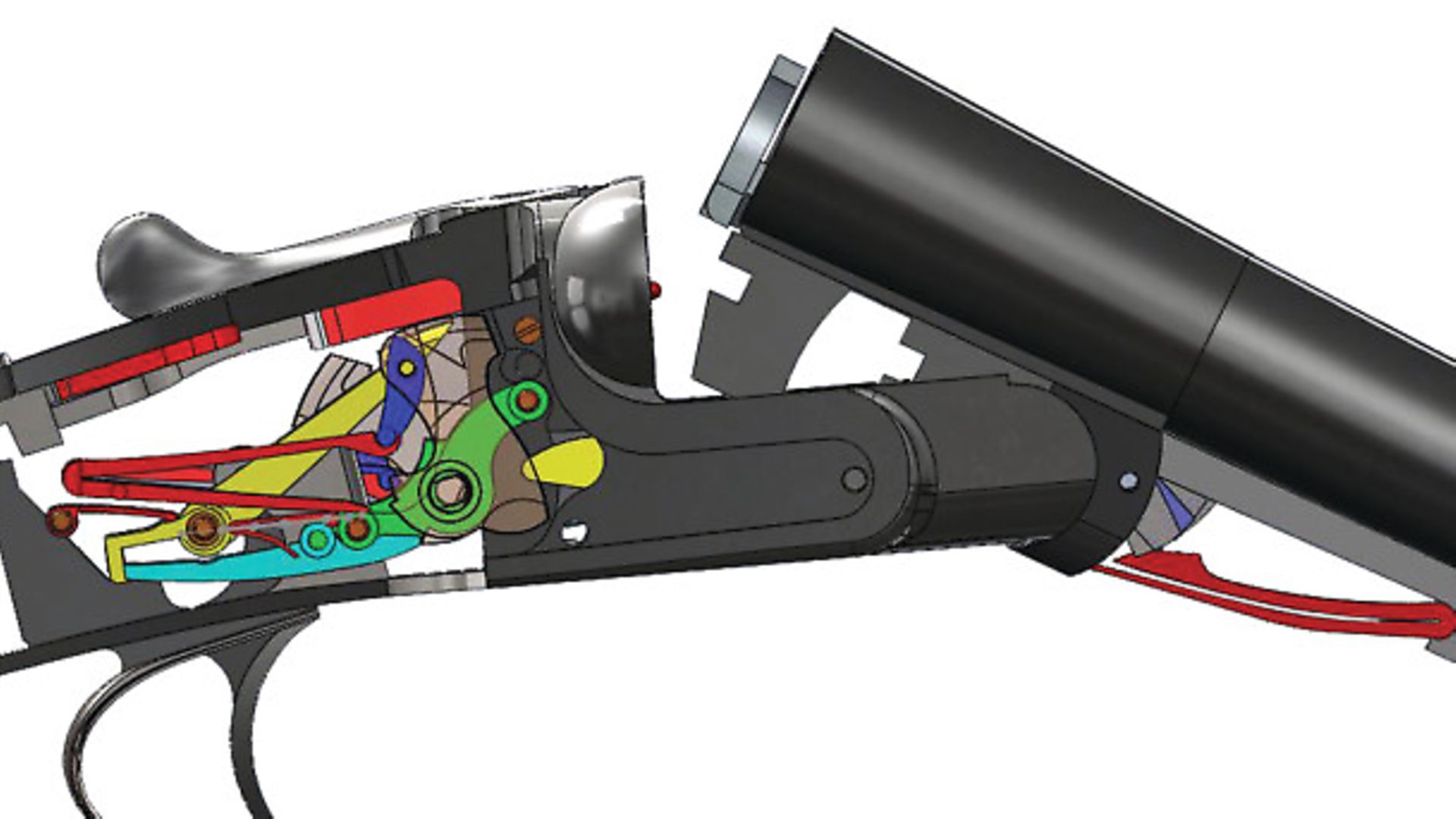

Demibloc and monobloc are names for two different methods of barrel construction on shotguns and rifles. ‘Bloc’ is the breech section of the barrels that fits into the action body. ‘Demi’ means half. ‘Mono’ means one. So simply put, a ‘monobloc’ consists of one piece, and a ‘demibloc’ consists of two pieces.

Demibloc

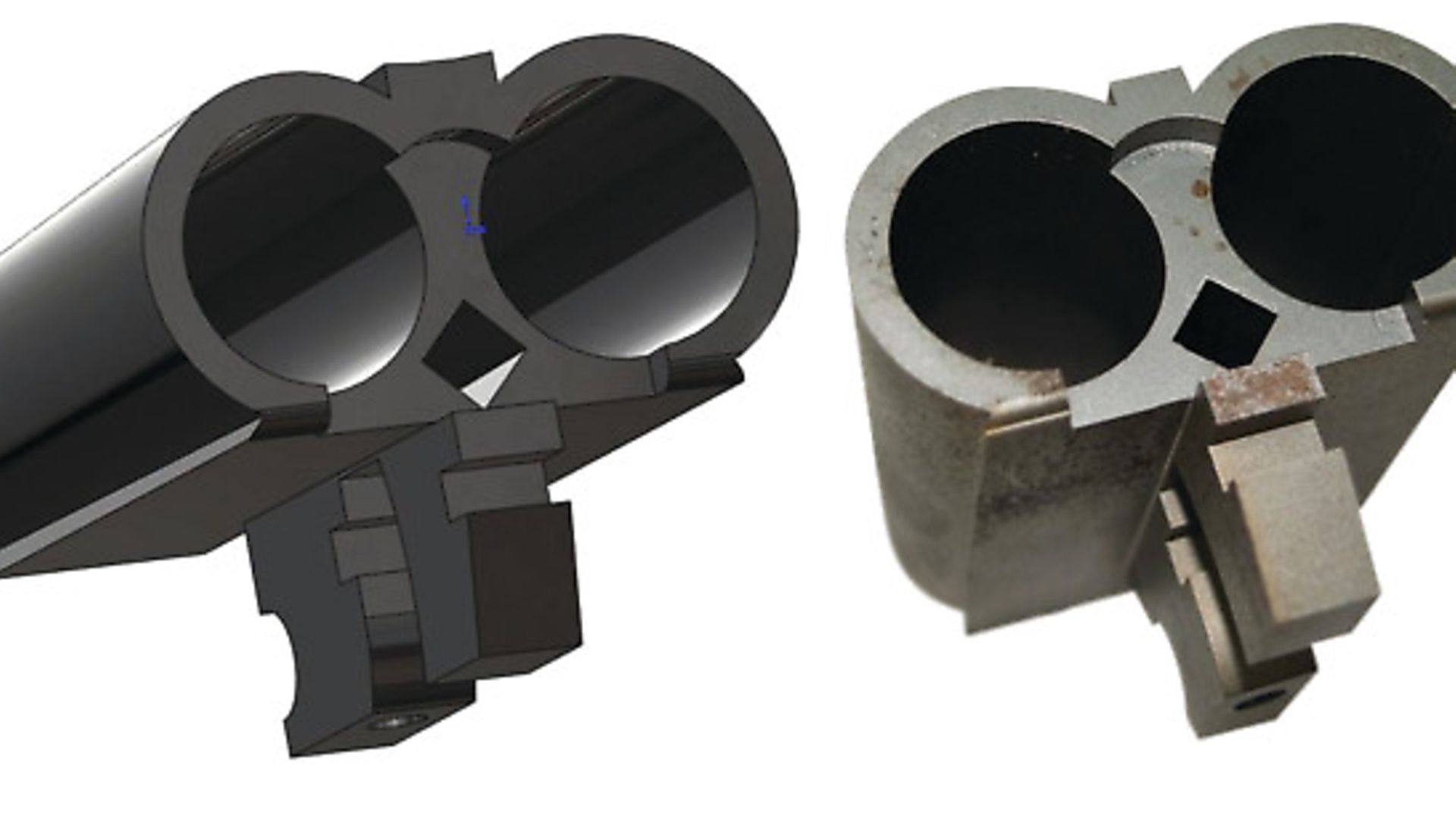

Demibloc is often referred to as a ‘chopper lump’ barrel – this is because the barrel with its lump looks like an axe, or ‘chopper’. Each barrel is formed from a single piece of steel, giving additional strength as the metal’s grain flows through the entire barrel.

The barrels are then fitted together with a braised join. This has to be accurately fitted to ensure the barrels converge at the correct angle – this ensures both the barrels point towards the same point of impact.

Monobloc

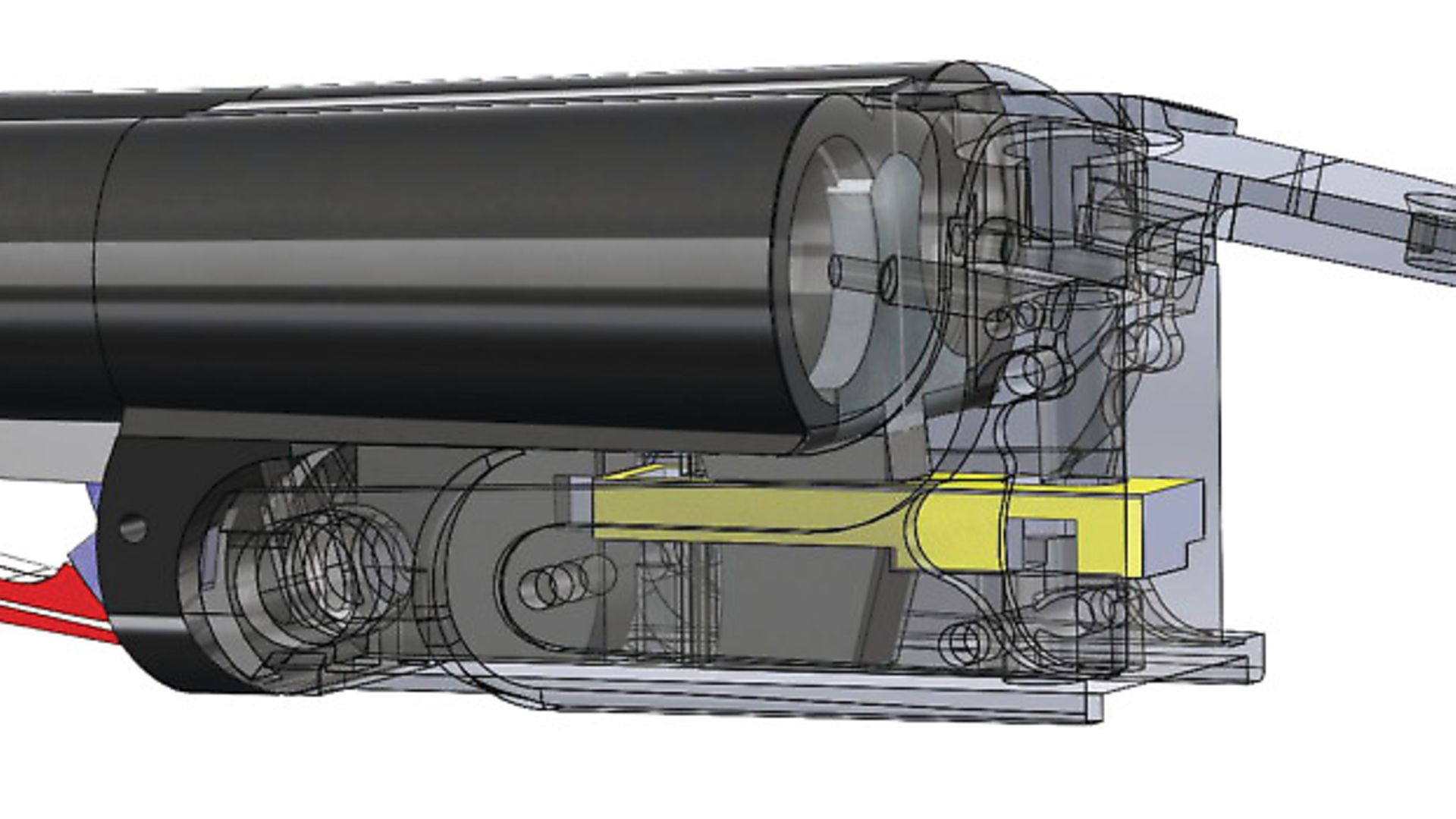

A monobloc barrel consists of a single machined component that the barrel tubes are braised into.

Advantages of demibloc

The main advantage of a demibloc barrel is strength. When a cartridge detonates, the shotgun is held shut by the ‘bite’ – the body bolt pushing down on the barrel lumps. The bite on a demibloc pushes down on both halves of the barrels, giving extra support.

Advantages of monobloc

The benefits of monobloc come from the accuracy of its manufacture – it can be machined to the perfect size. Angles can be machined to a tolerance of microns, and the convergence angles are added easily.

(With modern engineering barrel production has become far more advanced, and both demibloc and monobloc barrels have pros and cons that will be difficult to discern for most shooters).

Over-and-unders

When the above principles are applied to over-and-under shotguns the logic is turned on its head…

The lumps and bite are on the bottom barrel of a demibloc over-and-under, so when the gun is fired the only thing holding the top barrel into the action is the braised join between the two.

The strength of monobloc barrels on an over-and-under are far greater than that of demibloc barrels on over-and-unders, because monobloc are formed from a single piece of steel. It is also far more ‘machineable’ and the convergence angles and bite points are precision engineered, which is why most over-and-unders manufactured this way.

Related Articles

Get the latest news delivered direct to your door

Subscribe to Sporting Gun

Subscribe to Sporting Gun magazine and immerse yourself in the world of clay, game and rough shooting. As the leading monthly publication for passionate shooters at all levels, Sporting Gun delivers expert advice, practical tips and in-depth reviews to enhance your skills and enjoyment of the sport.

With features ranging from gundog training to pigeon shooting, and wildfowling to equipment recommendations, you’ll gain valuable insights from professional shooters and industry experts. A subscription not only saves you money on the cover price but also includes £2 million Public Liability Insurance, covering the use of shotguns, rifles and airguns for both recreational and professional use.