Hand tools are perhaps not the most glamorous of airgun subjects, but if you are prone to tinker, as I am, it’s vitally important that you make the right choices. As with all things in life, generally you get what you pay for, and hand tools, unless bought second-hand are no exception.

Over the 40-odd years that I’ve working on airguns, I’ve been able to amass a fair selection of tools – some good, some bad, and some downright ugly – and it’s my intention to look at a few staple tools from my own bench that fit or exceed the good category. I will warn you that some of these are not cheap, although they do represent the very best that is currently available, and will last the course. We are going to look principally at hex keys, punches, and screwdrivers, which for me represent foundation tools for the airgun workshop.

Hex Keys

Hex Keys

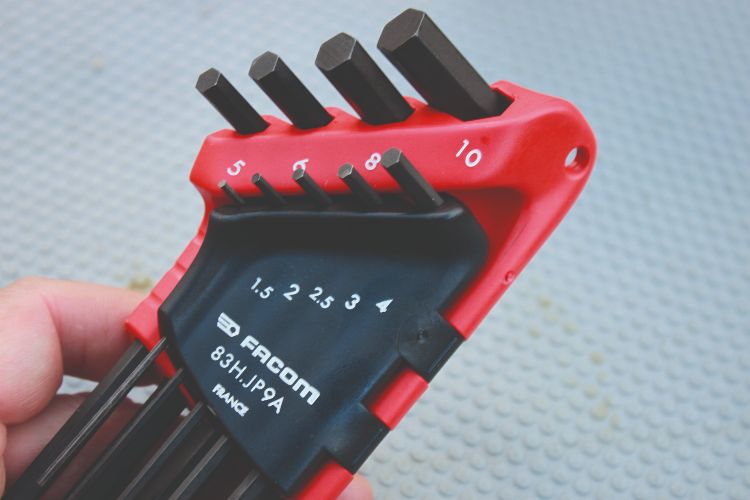

Hex head screws do seem to be getting ever more popular these days, even making appearances on spring guns. As with a slot- or cross-head screw, perfect fit is everything because if the hex head rounds out, the screw is scrap. Hex drivers can also wear, which in turn will effect fit, so the best way to assure fit and longevity is select a quality make, and I have two top picks here: Facom and Bondhus.

Facom are the biggest hand-tool manufacturing company in Europe, founded in 1918 in Paris. It’s a company that had humble beginnings with just one tool – the 101 spanner, also known as the 101 Madam. This chunky-looking adjustable spanner was their only tool for one year, before being joined by others, but despite this, the 101 spanner saw production into the 1960s.

The Bondhus company, founded by John Bondhus, in America in 1964, was born out of a need to produce quality hand tools that would be accessible to all. In fact, it was the production of hex keys that started the company, with the invention of the, ‘Ball driver’, now commonly seen on many hex keys.

Currently, I have two Facom-branded hex keys, a set of long-arm conventional keys and a screwdriver-type, or ‘spinner’ key. The long-arm set has a range of 1.5mm - 10mm, and that 1.5mm will be essential for trigger and transfer port adjustments on Air Arms guns. A long arm means that more torque can be applied to those errant grub screws, whilst the fit and overall strength will give you the best possible chance of success. Housed in a plastic, hinged case, so that they will always be together in one place when you want them.

My own set is parallel-tipped, and not ball-ended, although this option is available. I can well understand the rationale for a ball tip, which can be useful for occluded screws, but I’ve never encountered this scenario in airgun maintenance, and I do find the ball tip doesn’t offer the same level of contact as the parallel tip.

A hex spinner set is my latest addition, and is already becoming a favourite. With a range of 2mm - 6mm, housed in a neat roll, the pro-twist grip gives screwdriver-like performance in a hex key. They will not give the same torque as a long-arm set, but they resist the temptation to put too much pressure on screws when you are tightening them. This tool comes into its own not only for stock screws, but also for scope-mounting applications.

T-handle wrenches

T-handle wrenches

Guns such as earlier Daystates and Theobens, have imperial screws, so you will need a couple of different sets, and undertaking a service on a Rapid 7 seemed a good time to try a set of Bondhus imperial T-handled wrenches. Supplied with a stand-up, bench-top mount, these distinctive yellow-handled tools give maximum hand grip, and because of the weight of the handle, the flywheel effect allows screws to be undone and spun back in very quickly.

It is important to note that underneath the plastic handgrip there is a metal handle welded to the blade. In the past, I have used cheaper sets where the blade is moulded into a plastic handle, and needless to say, the blade starts turning in the handle at the first sign of real pressure.

A range of sizes 3/32 - 3/8 covers all the popular sizes you are likely to come into contact with, and having used this set for the past two years, I can vouch for its effectiveness and practicability.

punches

punches

Next to screws in airgun fixtures comes the parallel pin, which relies on a friction fit to hold its position. The correct removal requires a suitable sized parallel punch that has undergone the correct hardening and tempering processes. Contrary to popular belief, in some quarters, a ground-down nail is not the correct tool for the job. What we need is a purpose-made tool of high quality, and the correct size, which is what Starrett offer.

The Starrett company founded in 1880 by Laroy Sunderland Starrett, has built an enviable reputation amongst the engineering trade for making top quality products, which are used the world over. Their eight-piece, drive pin punch in sizes 1/16” - 5/16” will cover all the sizes encountered on an airgun rebuild. Don’t be concerned about the imperial sizing, these will be just fine on metric pins.

Beautifully engineered with tapered body and knurled grip, these really are the Rolls Royce of punches, supplied in a plastic wallet and cardboard box. Any keen airgun engineer would be proud to have a set of these in their tool box.

There is another type of punch frequently used in engineering – the centre punch. These are typically used to make an indentation in steel as a guide mark before drilling, helping the drill bit to keep from wandering. There will be times when the airgun engineer will need to use them for this purpose, although I have found myself using them on many occasions as a means of removing a screw with a damaged head. By using the tip of the punch on the outer edge of the screw it is possible to get the screw moving, when a conventional screwdriver would be useless. I used this method recently on an HW98 where the breech bolt nut had been so badly deformed that it was otherwise impossible to release.

Starrett’s five-piece, centre punch set is made to the same exacting quality standards as we have seen previously. The differing sizes offer plenty of choice for whatever application you have. The very fine 1/16” size was just perfect for a recent job on a AirArms TDR when I needed to centre-punch the end of a 3mm diameter pin before drilling into it.

Scewdriver

Scewdriver

The name ‘Halfords’ has become synonymous with UK road users, particularly those on two wheels. What perhaps is less appreciated is their line of advanced tools, which carry a lifetime guarantee. That guarantee covers breakages to their hand tools, and means just returning to a branch, where a replacement will be offered.

It’s the Halfords advanced screwdriver that has our attention here, though, because it’s a little cracker, with a very affordable price tag. I’m not sure where Halfords source their tools from, although I have it from a reliable source that they are made on the same factory line as some other well-known quality brands that shall remain nameless!

This screwdriver set comprises a soft, generous-sized handle and shaft which has the ability to accept different bits. There is a total of 32 bits, including; slot head, cross head, hex, and Torx – all differing sizes and covering most metric applications. The inclusion of Torx bits is interesting because they are now being seen on some guns. These bits can also save you some trouble if you have a badly damaged; carefully tap the Torx head into the slightly smaller hex head, and the sharp edges will effectively cut into the hex, allowing you to unscrew it for replacement.

I hope that I’ve given you some food for thought on tools for your own tool box. Maybe it’s time to take stock of its contents and plan for an upgrade! The take-home message here is to buy the best possible tool you can afford, then you can no longer blame your tools if a job goes wrong!