Jim Tyler studies what happens between the trigger and the muzzle when you fire an air rifle, and whether reducing barrel time or lock-time is worth it

I’m sure that most of us find it very difficult to hold an airgun anywhere near perfectly still when taking aim, most especially when taking shots as we bear the full weight of the rifle.

This is manifest in HFT shooting, in which nearly everyone will agree that the hardest target on the course is the single, unsupported standing shot, followed by the unsupported kneeling shot, and the problem is that the rifle is moving during the very short time between us pulling the trigger, and the pellet leaving the barrel. Put simply, at pellet exit, the rifle is not always pointing in quite the same direction as it was when we pulled the trigger.

Generally speaking, and for the reason given above, the shorter the time interval between the trigger sears parting company, and the pellet exiting the muzzle – often called the ‘shot development time’ – the better, and this applies to both PCPs and springers.

Distinct stages

The shot development time breaks down into two distinct parts; first comes the interval between the trigger sears parting company and initiating the shot cycle, and the physical process that causes the pellet to start moving, usually called the ‘lock’ time, and the second is the time it takes for the pellet to accelerate the length of barrel to the muzzle, which we’ll refer to as the ‘barrel time’. Either the lock time or the barrel time, or both, can be reduced to shorten the shot development time. Depending on the type of rifle, and the method(s) employed to reduce the shot development time, there could well be a price to pay.

Reducing barrel time in break-barrel air rifles

You could reduce barrel time by using a lighter pellet that accelerates more quickly to a higher muzzle velocity, but unless that pellet also happened to give the best accuracy, it would be a pointless exercise. The two other ways to shorten barrel time are to make your chosen pellet travel faster – not an option if it’s already close to the UK muzzle energy limit – or to shorten the barrel, and the latter is not something to be considered lightly.

In his book ‘The Airgun from Trigger to Target’, Gerald Cardew famously stated that the pellet in a typical .22 springer has accelerated to its final (muzzle) velocity in the first five inches of barrel travel, a figure quoted and misquoted ad infinitum in the quarter of a century since the book was published, and a figure that is, sadly, misleading.

You see, Gerald’s five inches of barrel acceleration applies only to springers with very short piston strokes, and we’re taking about 65mm or less. Had Gerald repeated the same experiment with a springer with, say, an 80mm stroke, such as the HW80, he would have found that the pellet accelerates way beyond five inches, because two talented engineers independent of each other, measured the pellets in .22 HW80s accelerating all the way to the muzzle of a 16” barrel.

Unless a springer has a particularly short stroke or an exceptionally long barrel, then reducing barrel time by shortening the barrel will cost you a little muzzle velocity (albeit only 1% to 2% per inch for a perhaps 14”+ barrel, increasing drastically the shorter the barrel) and if you want to recover the lost velocity, you will have to stiffen up the spring or increase preload, in both cases, increasing recoil travel. Add to that the fact that the loss of weight at the front of the barrel will in itself result in a small increase in recoil, and a larger increase in muzzle flip, and shortening the barrel suddenly becomes a less attractive idea.

credit: Archant

credit: Archant

Reducing barrel time in PCP air rifles

Because it uses four or more times the mass of air per shot as a springer, the typical PCP easily accelerates pellets the full length of the barrel, and shortening a PCP barrel can cost much greater muzzle velocity loss than shortening a springer barrel. Let’s put some figures to that.

There are a couple of concepts we need to address in order to understand what’s going on in the PCP shot cycle. The internal kinetic energy – a measure of ability to do work, such as pushing a pellet up a barrel – of a quantity of air molecules, depends only on its temperature and as the air performs the work of pushing the pellet, its internal kinetic energy, and hence its temperature, fall.

If we know the quantity of air molecules that will be used by a PCP during a shot cycle, and we know its start temperature, we can calculate its internal energy, and if we know the volume that air is contained within before the shot is taken, and we can calculate the volume to which it will have expanded as the pellet is on the point of exiting the muzzle, we can calculate its end temperature, and from that, the amount of energy in the air that follows the pellet out of the barrel. The difference between the start and end energy is the amount of energy used in accelerating the pellet, plus any losses.

The maths!

If a PCP uses 200cc of air at standard temperature and pressure (20ºC and 14.7psi) per shot, and if the start temperature is 293K (20ºC+273), the air’s internal energy works out at 200 x 0.0012929 x 293/1.4, or 54.38 joules, or 40.11 ft.lbs.

Let’s say the air is compressed to 160 bar, that means its start volume is 1.3cc, and if it is a .177 with a 400mm barrel, the end volume (including the transfer port) might be 7.9cc.

The end temperature is simply ((1.3/7.9)^0.4) x 293, or 142.34K, so its end energy is 200 x 0.0012929 x 142.34/1.4, which works out at 26.29 joules, or 19.39 ft.lbs. Subtract 19.39 from 40.11, and the energy used to drive the pellet (plus losses) works out at 20.72 ft.lbs.

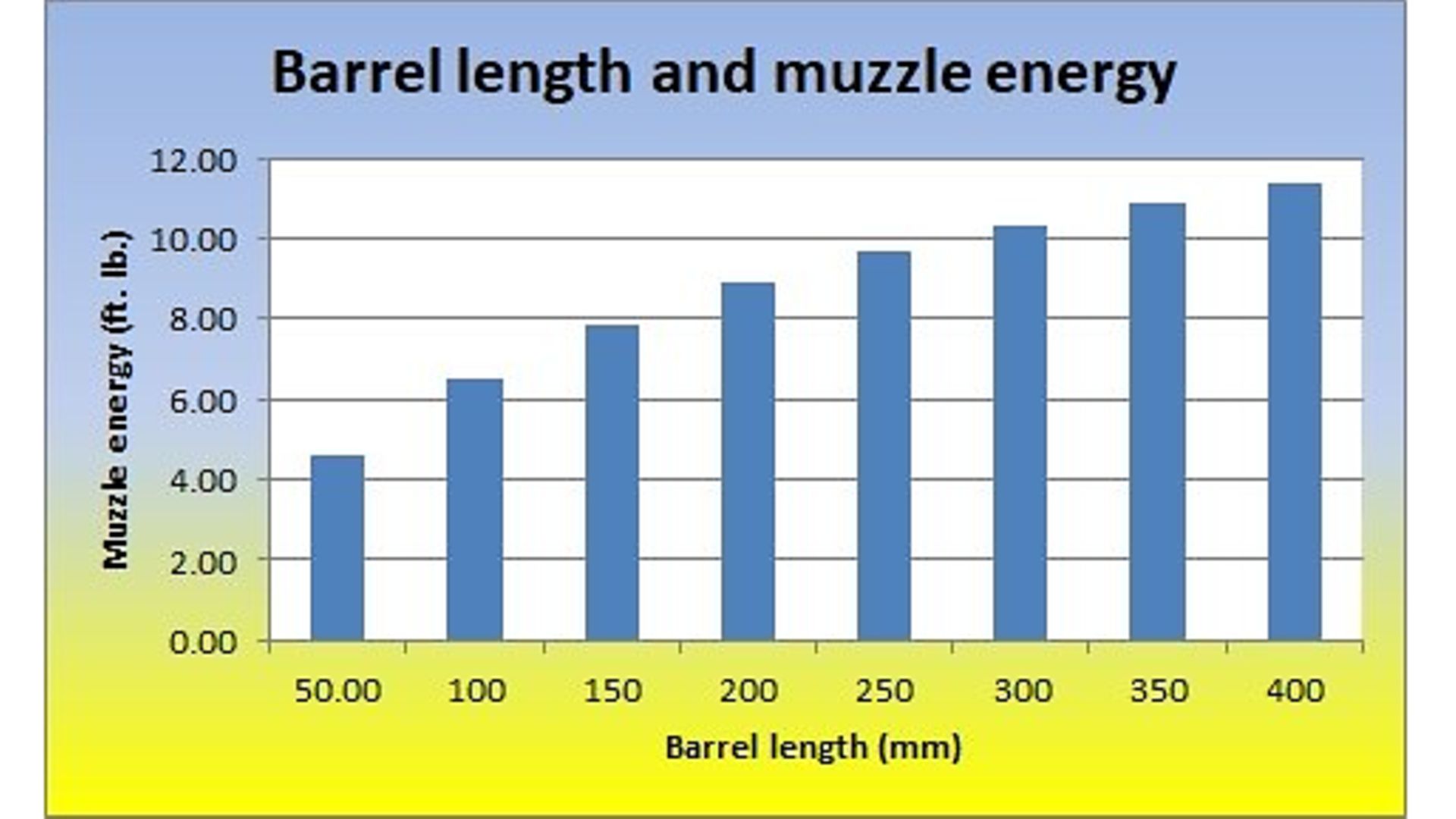

Once you know how much energy is used in a shot cycle, you can actually test the rifle with your chosen pellet, and find the percentage efficiency of the rifle. If our fictitious rifle gives a muzzle energy of 11.35 ft.lbs., then the efficiency is 11.35 /20.72 x 100, or 54.8%. Once you have that energy efficiency figure, you can redo the temperature and energy calculations for any length of barrel you like, and get a very good idea of what the effect of shortening the barrel will be, and for the example above, the muzzle energies are shown on the graph ‘Barrel length and Muzzle energy’.

In round numbers, shortening a 400mm-long PCP barrel by 50mm (2”) will reduce barrel time by a mere 0.0002 seconds, and lose just under half a foot pound; and shortening the barrel by 100mm (4”) will shorten barrel time by just 0.00043 seconds and lose a full foot pound. In both cases, quite a price to pay for so little gain.

credit: Archant

credit: Archant

Shot development time

One final consideration before shortening a barrel, on a PCP or a springer, to reduce barrel time, is that not all barrels have strictly parallel bores, and if you chop a barrel at a slack spot, accuracy will be a distant memory. In the past, I have successfully choked a slack muzzle using heat and ice, but the results are by no means guaranteed, so please bear all this in mind before chopping a barrel.

Reducing lock time in PCPs and springers

Although there is an infinitesimal time interval between the sears parting company, and the hammer starting to move, the lock time in a PCP is overwhelmingly governed by the hammer travel, and the only ways to speed things up would be either to reduce the travel distance –essentially re-engineering the action – or to increase hammer acceleration by fitting a stiffer spring with less preload.

That means very few people will be competent to reduce PCP lock time, and the rest of us are stuck with what the design dictates.

PCP lock times are in the order of a few milliseconds (my S510 hammer takes only 4.6 milliseconds to reach the valve), and so even were I able to reduce hammer travel, or fit a stiffer spring, the reduction would be so slight that, for me, it would definitely not justify the work needed.

In the springer, again there is an infinitesimal time interval between the sears parting company and the piston starting to move, but it is so tiny that the lock time is overwhelmingly governed by piston travel time, and that is easily varied in a springer by altering the distance it travels, the acceleration, or both. Often, though, varying piston travel or acceleration comes at a price.

I have a long history of shortening airgun piston strokes, starting in the mid-1980s with an Original (Diana) 45, in which I had replaced the leather piston seal with one made from PTFE, and which subsequently gave far too high a muzzle energy until I extended the piston face to reduce the stroke and bring the muzzle energy down to under the legal limit. In more recent times, I have short-stroked HW95s, my HW77 and TX200s, and learned valuable lessons along the way.

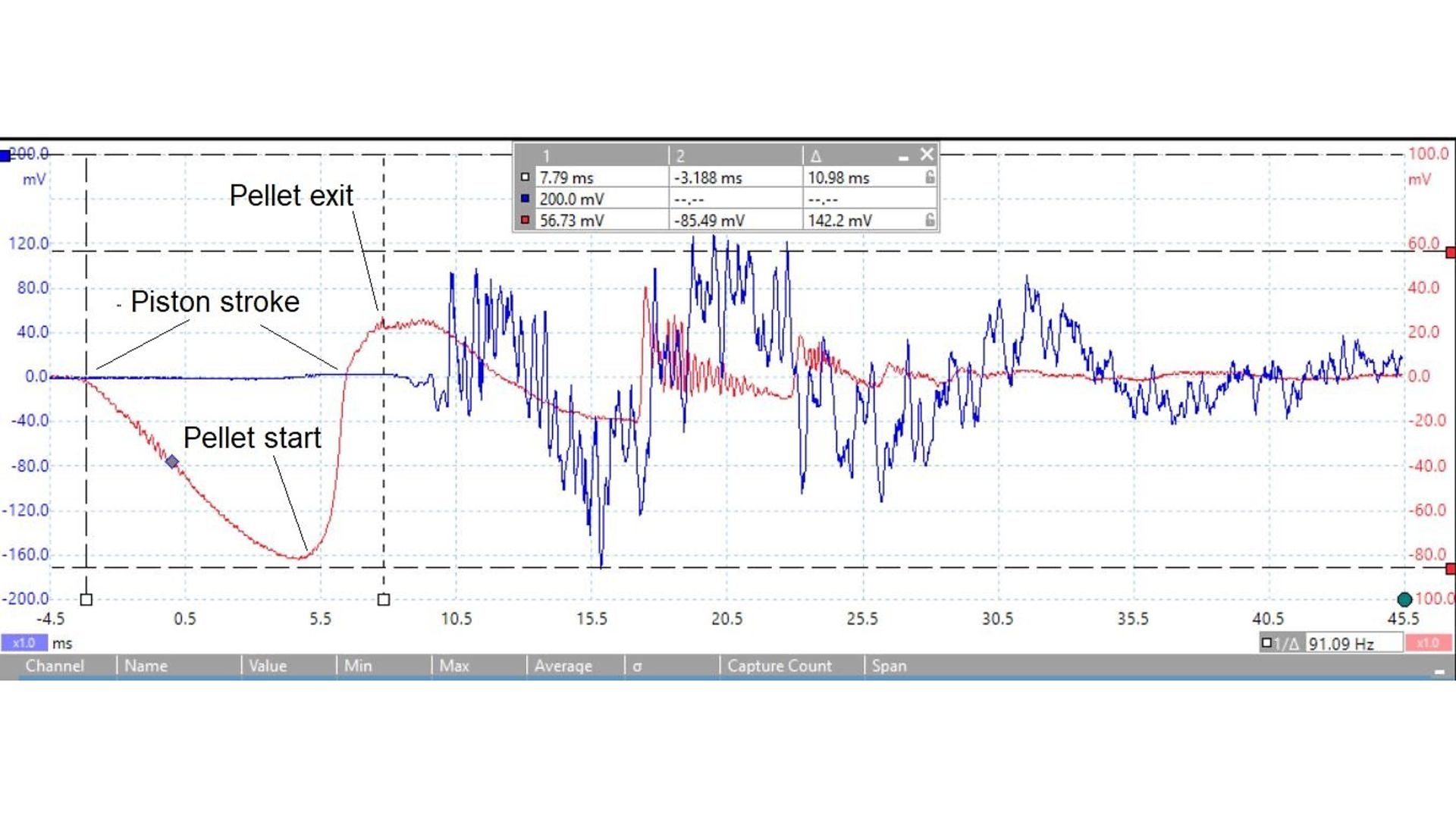

It is important to recognise that what we call ‘the lock time’ could be taken to mean either the time the piston travels before the pellet starts to move, or the time the piston takes to complete the compression stroke. Because it is difficult to determine precisely the point in the piston stroke when the pellet starts to move, I record the full compression stroke, which means that the ‘lock’ and barrel times I record overlap within the overall shot development time.

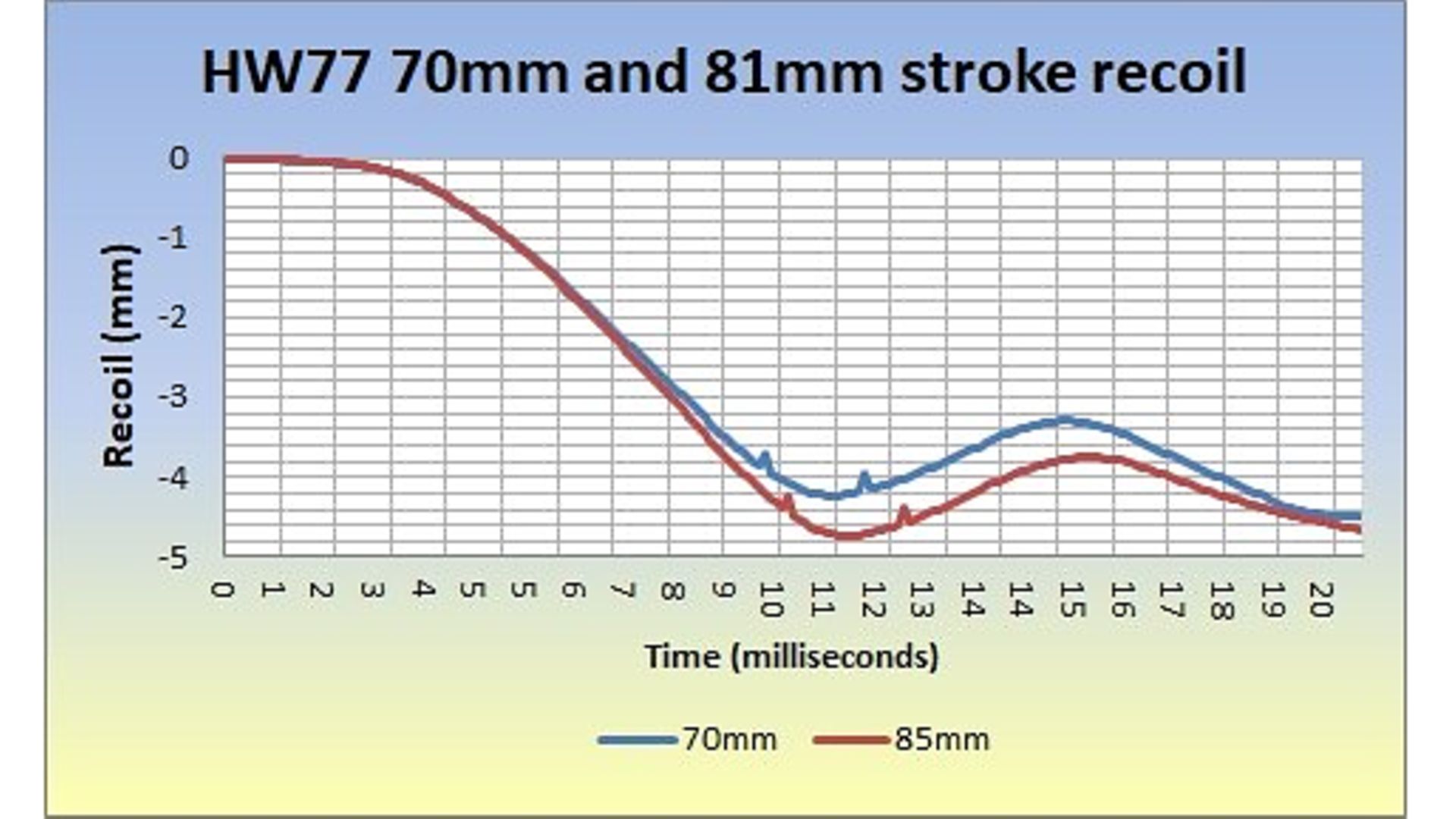

The first lesson I learned was that it is possible to make the stroke too short, when I reduced the stroke of my 25mm cylinder HW77 from 81mm to 70mm. The rifle felt superb to shoot with less than 4mm of recoil travel, and it was certainly quick, with the pellet out of the muzzle in ten milliseconds. What was lacking was accuracy.

Increasing the HW77s stroke to 75mm added just over half a millisecond to the lock time, increased recoil travel by 7%, but (at least) partially restored accuracy, whilst returning the stroke to the original 81mm restored accuracy and suggested that Weihrauch had got it right all those years ago.

With my Mk.3 TX200s, after trying 81mm stroke, I opted for a conservative reduction in stroke to 85mm, and it was just ‘right’ in every respect. The vital statistics are ~4.5mm of recoil with a 500gr scope, a 9.2ms compression stroke, and a shot development time of 10.5mm – 11ms depending on pellet. Those figures aren’t terribly impressive, but the utter reliability is, to the extent of seeing a full four seasons of HFT competitions without so much as a scope tweak.

You can also shorten the springer shot development time by fitting a stiffer mainspring, with reduced preload to keep it legal, and in fact, this is exactly how many airgun tuners approached their work for decades.

The stiffer the mainspring, the faster the piston acceleration, so the shorter the compression stroke time. That sounds great, until you learn that the nature of the recoil is governed by the nature of the compression stroke, and a faster accelerating piston means a faster accelerating rifle. Rapid recoil acceleration is only half the story, because the reduced preload needed with a stiffer spring offers lower force to counteract piston bounce and consequent recoil surge, so the rifle is surging forward faster at the point the pellet exits the muzzle, which is not desirable.

credit: Archant

credit: Archant

Weight

Reducing piston mass (weight) will quicken the lock time, but because the air is compressed by the momentum of the piston (weight times mass), reducing the mass means that faster piston speed is needed to compensate, and with less mass to counter the force that drives piston bounce and consequent recoil surge, the piston bounce will be faster when the pellet exits the muzzle, which as I have already suggested, is not desirable.

Friction

The final way to quicken the lock time is to reduce piston-seal friction by using a piston ring of some kind in place of the more usual synthetic parachute seal, but as ever, there’s a drawback, which is that piston-seal friction works both during the stroke and the bounce, so again, the rifle is surging forward more quickly at pellet exit.

Cost and benefit of reducing shot development time

Whilst reducing the shot development time is undeniably a great benefit, the extent by which it is reduced, and the method by which it is reduced, can come at a price, which in the fullness of time might prove too great.