Tim Finley explains how to check for obvious problems on a PCP rifle that might affect your accuracy if your pellets are suddenly flying off-course.

Pre-charged pneumatic air rifles were a game changer. I began my competitive shooting with spring-powered air rifles, but I was lucky to be able to experience the rise of the PCP to dominance in field target shooting. One thing we learned very soon was they have certain design characteristics that can cause pellets not to fall where the shooter intends them to drop, but there are things you can look at that might be at fault. That’s after you’ve done the basic checking of the scope mount screws, both on the rings and the ones clamping the scope mounts to the gun.

Stock screws

Stock screws

On the rifle, first check the stock screws. A pre-charged pneumatic air rifle normally has only one stock screw, so that is easy to check, and the trigger guard is normally just attached to the stock.

There are two schools of thought about how tight the stock screw on a PCP should be. I’ve known quite a few top FT and even HFT shooters who barely tighten their stock screws, or even have the action loose in the stock, but I’m most certainly in the other camp of those who like their actions to be held firmly in the stock because there are potential problems here, if the stock isn’t fitted correctly to the action.

If the stock contacts the compressed air cylinder at the end of the stock, or even on one side only, then it can move the zero by a significant amount, depending upon the pressure in the cylinder, or the temperature of the air outside the cylinder and the rifle itself.

Checking the gap between air cyclinder and stock

Checking the gap between air cyclinder and stock

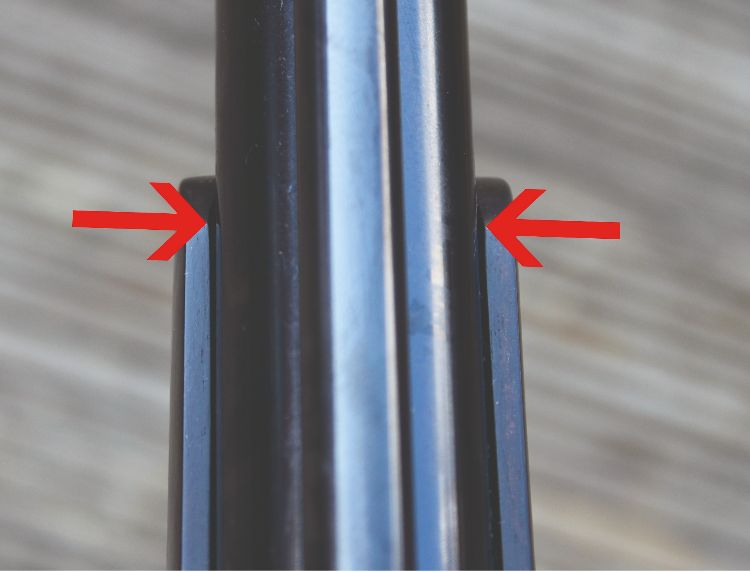

All well-designed wooden PCP stocks are recessed on their internal surfaces where the air cylinder is located, from the very front end of the fore stock to the breech block, to allow an air gap the full length of the air cylinder.

You can check if you have this gap on your PCP stock by sliding a piece of paper, or a UK plastic bank note down the length of the air cylinder. If it will not slide all the way from the front end of the stock, all the way back to the action, you have problems. It should only stop when it reaches the trigger block, or pressure gauge position. Make doubly sure that the stock screw is tight before you try the gap test. You need to mark the position where the paper stopped – I stick some masking tape to the outside of the stock, roughly where I can see the paper being stopped.

You can either attack the inside of the stock with a Dremel on the offending raised area, or there is an alternative, if the amount that it is catching by is not too much. I fit plastic shims with double-sided sticky tape to the inside of the stock, under the breech block and around the stock screw hole, to ensure that when the action is tightened back down it creates the desired even gap all around the air cylinder. this is by far the best way to ensure a PCP does not change zero every time you re-fill it with compressed air.

You can either attack the inside of the stock with a Dremel on the offending raised area, or there is an alternative, if the amount that it is catching by is not too much. I fit plastic shims with double-sided sticky tape to the inside of the stock, under the breech block and around the stock screw hole, to ensure that when the action is tightened back down it creates the desired even gap all around the air cylinder. this is by far the best way to ensure a PCP does not change zero every time you re-fill it with compressed air.

The other good thing you can do is use differing shim thickness. If the stock is not aligned to the action, you can centralise it with the use of thick shims on one side, and thin on the other. Fine-figured walnut stocks may look nice, but laminated stocks do not alter their shape in differing temperatures, and humidity is compared to solid wooden stocks.

Checking the figure-of-eight clamp

Checking the figure-of-eight clamp

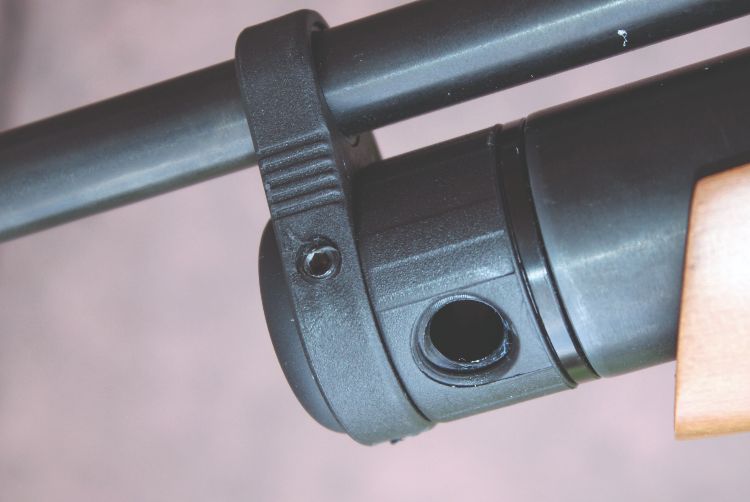

PCPs can also have a figure-of-eight clamp on the end of the air cylinder, into which the barrel also fits. If this is not aligned to have the bore of the barrel in line with the action, it can cause pellet cross-over downrange.

I use two steel parallel bars, one placed at the breech block, and one at the filler-cap end, to line up my barrel-to-actions. They rest upon the barrel and the air cylinder and when you look down the action you can see if the two are aligned with one another. With a semi-tightened figure-of-eight clamp you can turn this to line up the two bars. Once the Allen screws on the clamp have been tightened, I scratch a barely discernible match mark along the clamp and cylinder so I can see that they are lined up and can refit the clamp to this mark without having to resort to the bars again.

Check your moderator is tight

Check your moderator is tight

For hunting rifles that have a screw-on moderator, you have to make sure that the moderator is tight up to the shoulder of the barrel thread. Even a tiny gap and the gun will tend to throw pellets about with abandon. Make sure the internals of the moderator are where they should be and are not moving about. A pellet clipping a moderator can ruin the moderator as well as sending the pellet in a completely unexpected direction.

On the bolt of a bolt-action rifle, take a look at the condition of the ‘O’-ring on the bolt probe. Any splits or cracks in it will affect the power output of the gun and thus the accuracy; i.e. if the ‘O’-ring opens up on a shot, that will drop lower than expected due to the loss in power. Speaking of power, please remember to fill up your PCP before a zero session, and always fill them to the same pressure – with knock-open valves, fine-tune the fill pressure to flatten the curve of fps. If you have a manual pump, then of fill to the same pressure every time.

DON’T PANIC!

DON’T PANIC!

Do not panic or be surprised to see your zero shifting throughout the year, either – the colder, denser air in winter will cause your pellets to drop lower than in summer. Outdoor airgun shooting is a truly fascinating, if not challenging game, which is why we all love it, right?