When it comes to vintage firearms, the barrels can make or break your investment. Diggory advises on when to rebarrel and how to delay this with proper care and attention

credit: Archant

credit: Archant

If you have an old shotgun, the most expensive part of it that is likely to wear out is the barrel (or barrels). In theory, there is nothing on a gun that cannot be replaced, although the cost could be a prohibiting factor in many cases.

That being said, if you find a gun with a really crisp action and lots of colour hardening, you can restore it very effectively and produce a custom vintage gun of your own specification by having a new stock and barrels made to suit your needs. However, this is an exercise that will probably cost you in excess of £20,000, so isn’t an option in most cases. Still, cheaper than ordering a new gun. A lot cheaper.

For most of us, the barrels are the key to a gun’s viability. If they are worn out, then you are unlikely to want to have new ones made. You won’t get much change out of £10,000 if you do, and you can buy a very nice vintage sidelock for that kind of money. If you have a 1920s Purdey, for example, and want new barrels, the A.N. Other barrel maker option will cost you the price I mentioned above, but ‘genuine Purdey barrels’ are currently being quoted at something close to £30,000 by the firm in South Audley Street.

Sleeving is another option, with various barrel makers charging for the service anything between £750 and £3,000, depending how meticulously they strike up, balance and profile the new tubes. As with most things, you get what you pay for. However, if you need your Army & Navy boxlock sleeved, there is no point spending the top figure on the job, in the same way that it is a false economy to sleeve your otherwise mint Holland & Holland ‘Royal’ sidelock with cheap tubes and a budget strike-up.

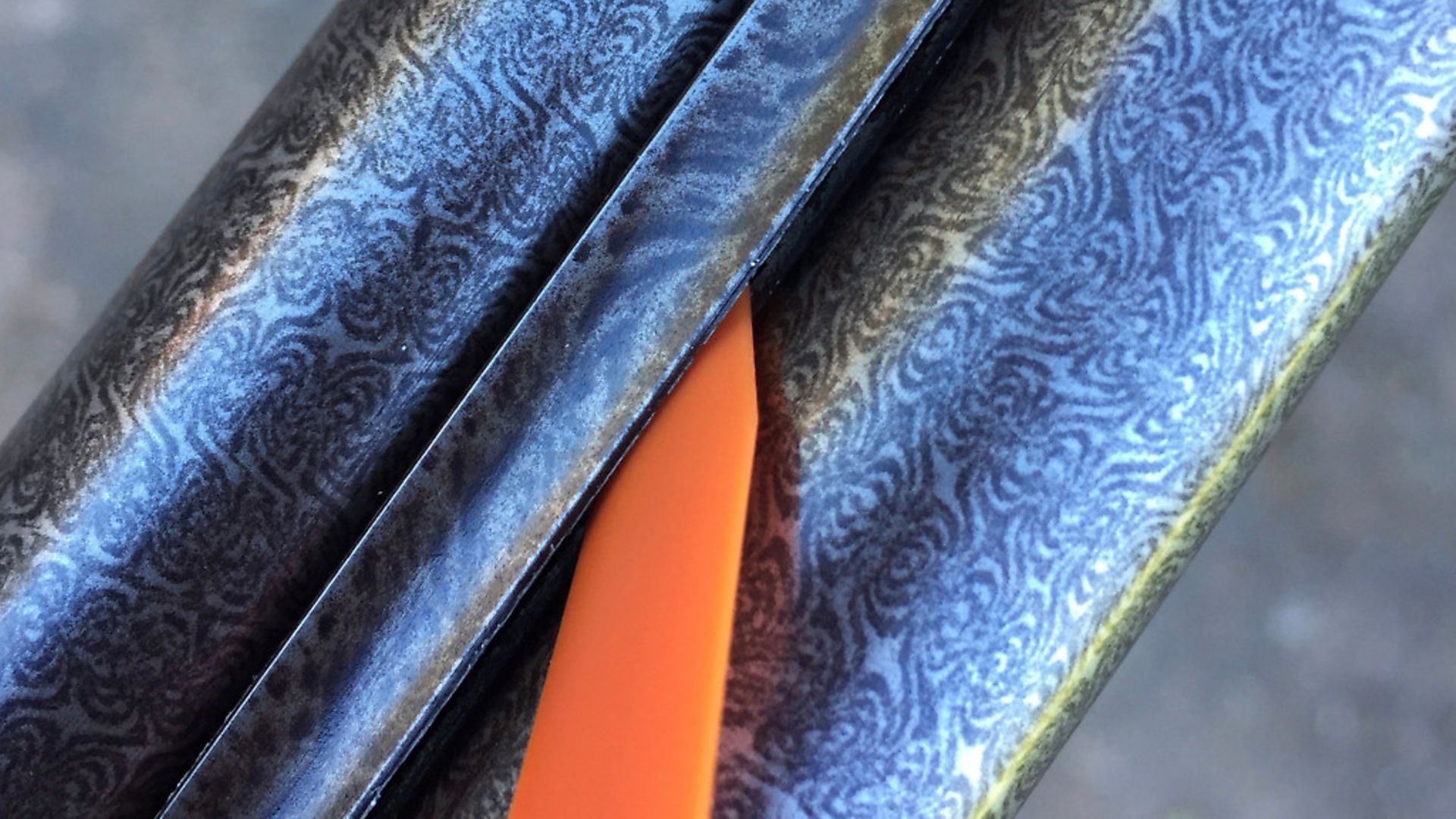

However, it is best to never have to face the thorny issue of what to do with your worn out barrels. Better, by far, to make sure you don’t buy a gun with this problem and that you learn how to spot trouble before it becomes terminal. Most English gun barrels of the pre-war vintage are made of a number of components: barrel tubes, lumps, top rib, bottom rib, quarter rib, loop, bead and (internally) packing pieces.

credit: Archant

credit: Archant

Fitted into the breech end will be the extractors. The lumps will generally be brazed on (unless they are chopper lumps, which are forged as integral parts of the tubes). Everything else is soldered together. It is, perhaps, no surprise that some of these soldered joints are beginning to fail after a century or more of the vibration and stress that they get in use.

Finding your barrels don’t ‘ring’ like a bell, when suspended from the hook and tapped with a knuckle or pencil, is often cited as a reason to panic. It is not. If the tubes are in good condition, stripping off the ribs, relaying them and then polishing and reblacking (or browning) is a straightforward job for a skilled barrel maker.

Before you condemn the ribs, do be sure to check that the problem is not the loop (which holds the fore-end to the barrel). If this is loose, it will give the same warning ‘thud’ when the barrels are tapped. Refitting the loop is an easier and cheaper fix. It is always worth carefully checking these when a gun comes back from reproof. The stress of the proof test often loosens the loop or the rib and the fact is frequently missed by the proof house.

As I write, I have three guns with loose ribs in need of attention in the workshop, awaiting remedial treatment. One is a Horsley hammer gun with Damascus barrels, which is in otherwise very good original condition. The second is a16-bore Purdey sidelock non-ejector with Whitworth steel barrels and the other is an 1890s Dickson round-action 12-bore with Damascus barrels.

In two of the three cases, I have customers reluctant to part with the cash to fix the fault properly. It is a problem I encounter frequently; they would prefer to just run a bit of solder under the rib. In my view, that smacks of a dodgy dealer doing a cheap fix before flipping a gun for a profit. If you are lucky enough to inherit a Purdey, you should look after it properly.

I’m reminded of a story one of my gunmakers told me, years ago, about an old aristocrat who sent his Boss in for servicing periodically. It was pointed out that there was a gap in the solder on the top rib and that moisture was getting in.

He refused to spend the £400, or so to deal with it. He continued to overlook his issue for the best part of a decade, at the end of which the rib totally sprung and he was informed that the rust between the tubes was so bad that the barrels were no longer safe and were, in effect, scrap.

Unsurprisingly, he wouldn’t consider rebarrelling and insisted on the cheapest sleeving job possible. In 10 years, through his unwillingness to spend £400 he turned a lovely, original Boss sidelock worth £20,000, into a badly sleeved imitation of itself, now worth £5,000, and it had cost him £1,000 in the end to achieve that!

So, pay attention to your ribs and your loops, and remember that shotguns, resilient as they are, are mechanical creations which do need ongoing care and maintenance to keep them in top order. A little money spent early will save you a lot of money down the line – and, more importantly, lots of heartache.